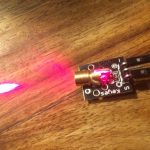

Took me a while to find the purpose of this little device I had in the mail recently. it’s a light detection sensor, which I connected to the arduino nano to test its functionality. it servs the amount of light from 0 (very bright) to 1024 (very dark) using the analog pin. To use this device with the ESP8266 you’ll probably need to adapt the voltage and transform it between 0-1V. But for now, it works fine costing around 2 EUR 🙂

void setup ()

int sensorPin = A0; // select the input pin for the potentiometer

int ledPin = 13; // select the pin for the LED

int sensorValue = 0; // variable to store the value coming from the sensor

void setup ()

{

pinMode (ledPin, OUTPUT);

Serial.begin (9600);

}

void loop ()

{

sensorValue = analogRead (sensorPin);

digitalWrite (ledPin, HIGH);

delay (sensorValue);

digitalWrite (ledPin, LOW);

delay (sensorValue);

Serial.println (sensorValue, DEC);

}

Output looks like this (analog):

21 -> bright 90 68 63 81 81 83 89 78 85 99 558 897 822 882 864 -> dark

For the webinterface I wrote a small external javascript file, which gets called by the esp8266 on most web requests. It fetches the temperature by json and visulizes it with d3.js in real time. The scales fit to the measured temperature and time automagically. It further is possible to display the site on multiple clients without loosing data or performance.

For the webinterface I wrote a small external javascript file, which gets called by the esp8266 on most web requests. It fetches the temperature by json and visulizes it with d3.js in real time. The scales fit to the measured temperature and time automagically. It further is possible to display the site on multiple clients without loosing data or performance.